Course Overview

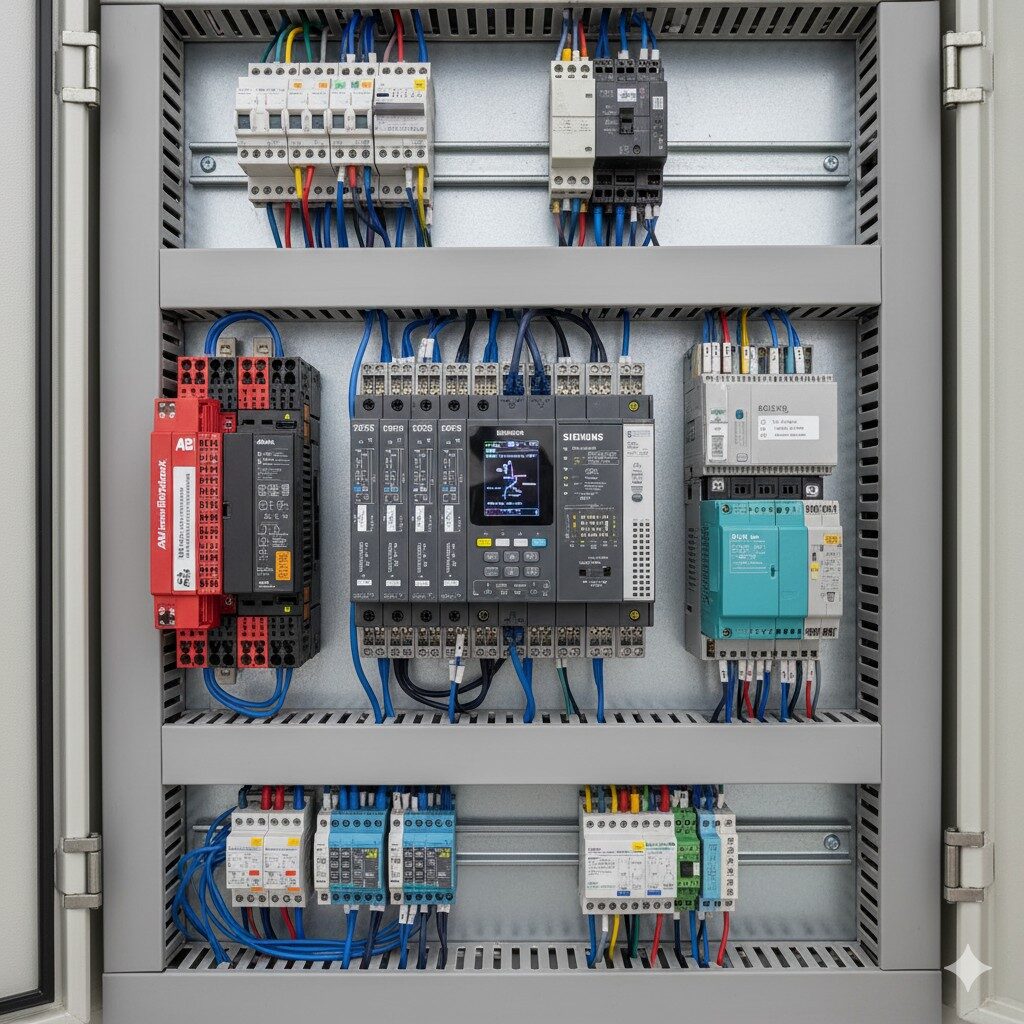

PLC (Programmable Logic Controller) is the backbone of industrial automation and control systems. This course teaches students how to program, design, and troubleshoot PLC systems used in manufacturing, process control, and automation industries.

Why Enroll?

✔️ Learn to program and operate PLC systems used in real industries.

✔️ Gain hands-on experience with industrial automation tools.

✔️ Understand control logic, timers, counters, and input/output systems.

✔️ Work on practical projects to simulate real industrial processes.

✔️ Enhance career opportunities in automation, manufacturing, and control engineering.

Who can choose?

✔️ Electrical, electronics, and instrumentation engineering students.

✔️ Beginners interested in industrial automation and control systems.

✔️ Students aiming for careers in PLC programming, automation, or industrial control.

✔️ Anyone looking to gain practical skills in modern industrial technology.

What You’ll Learn?

✔️ Basics of PLC hardware and software.

✔️ Programming PLCs using ladder logic and functional block diagrams.

✔️ Timers, counters, and input/output control.

✔️ Troubleshooting and maintenance of PLC systems.

✔️ Integration with sensors, actuators, and industrial machinery.

✔️ Hands-on projects simulating real-world automation scenarios.

Career path

✔️ PLC Programmer – Design and implement control logic for industrial processes.

✔️ Automation Engineer – Develop and maintain automated systems.

✔️ Control Systems Engineer – Manage industrial control projects.

✔️ Industrial Technician – Operate and troubleshoot PLC-based systems.

✔️ Process Engineer – Optimize production systems using automation technology.

PLC training equips students with practical industrial automation skills, preparing them for high-demand roles in manufacturing, process control, and industrial engineering.