Course Overview

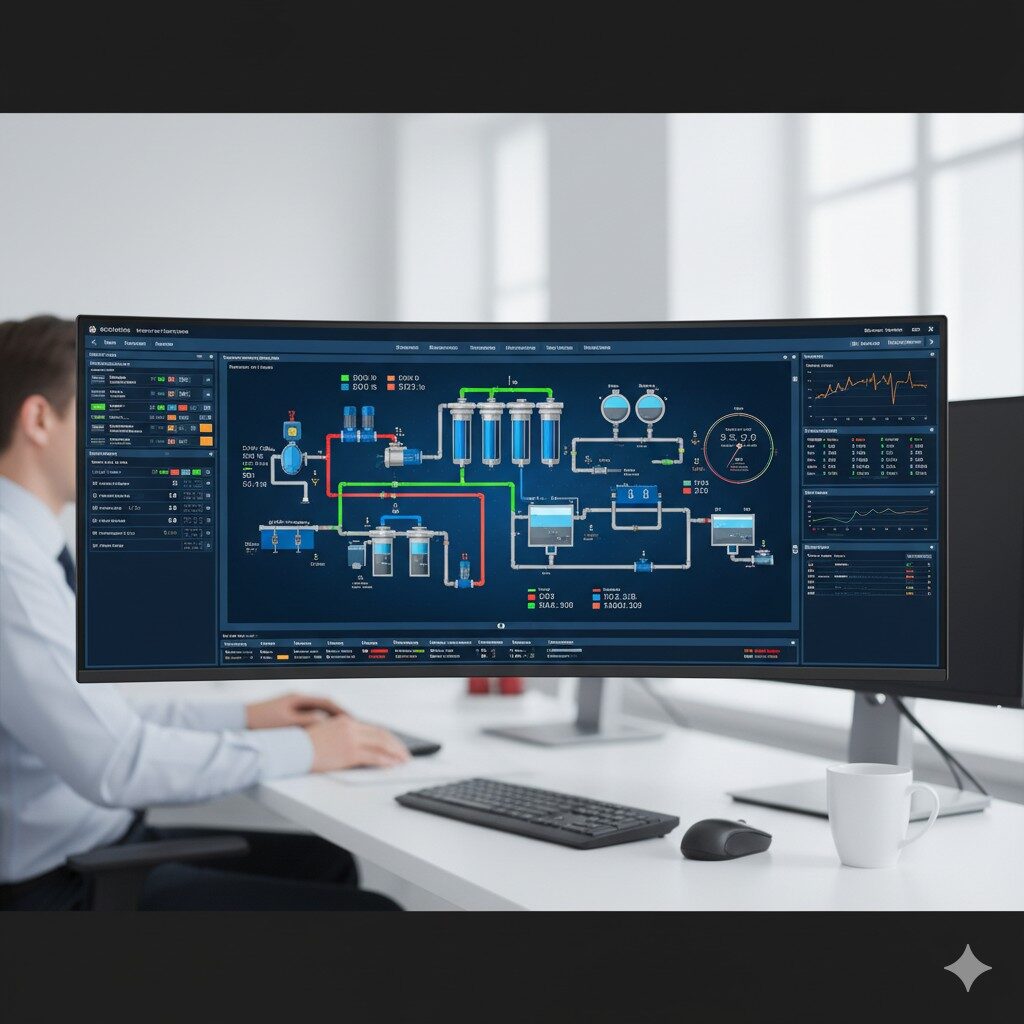

SCADA (Supervisory Control and Data Acquisition) is a critical system used in industrial automation and monitoring. This course teaches students how to monitor, control, and optimize industrial processes using SCADA systems, combining hardware and software for real-time management.

Why Enroll?

✔️ Learn to design and operate SCADA systems for industrial applications.

✔️ Monitor and control processes in real-time efficiently.

✔️ Gain hands-on experience with SCADA software and hardware integration.

✔️ Work on practical projects simulating industrial automation.

✔️ Enhance career opportunities in manufacturing, energy, and process industries.

Who can choose?

✔️ Electrical, electronics, and instrumentation engineering students.

✔️ Beginners interested in industrial automation and process control.

✔️ Students aiming for careers in monitoring, control, and industrial systems.

✔️ Anyone looking to gain practical skills in modern automation technology.

What You’ll Learn?

✔️ Fundamentals of SCADA systems and architecture.

✔️ Real-time data acquisition and monitoring techniques.

✔️ Integration of PLCs, sensors, and actuators with SCADA.

✔️ Designing and configuring SCADA software for industrial processes.

✔️ Alarm management, reporting, and control optimization.

✔️ Hands-on projects simulating real-world industrial scenarios.

Career path

✔️ SCADA Engineer – Design and maintain SCADA systems for industrial applications.

✔️ Automation Engineer – Implement control and monitoring solutions.

✔️ Process Control Engineer – Optimize industrial processes using SCADA.

✔️ Instrumentation Engineer – Integrate sensors and automation tools.

✔️ Industrial Consultant – Provide solutions for process monitoring and control.

SCADA training equips students with practical skills in industrial monitoring and automation, preparing them for high-demand careers in manufacturing, energy, and process industries.